Injection moulding is a popular manufacturing process used to produce plastic parts of various shapes and sizes. From small components like bottle caps to large parts like automotive body panels, injection moulding is a versatile and efficient method of production. If you're new to the world of manufacturing or simply curious about how everyday plastic items are made, this guide will provide an introduction to the process of injection moulding.

What is Injection Moulding?

Injection moulding is a manufacturing process used to produce complex plastic parts. It involves injecting molten plastic material into a mould, where it cools and hardens to the configuration of the mould cavity. Once the plastic has fully cooled, the mould opens, and the part is ejected, ready for any necessary finishing touches.

The Injection Moulding Process

The injection moulding process can be broken down into four main stages:

1. Clamping: The two halves of the mould are secured in the injection moulding machine. One half is attached to a movable platen, while the other is fixed.

2. Injection: Molten plastic is injected into the mould under high pressure. This ensures the plastic reaches all areas within the mould.

3. Cooling: The plastic inside the mould begins to cool and harden, taking on the shape of the mould cavity.

4. Ejection: Once the part has fully cooled, the mould opens, and the part is ejected. The process then repeats for the next part.

Types of Injection Moulding

There are several types of injection moulding, each suited to different production needs:

1. Overmoulding and Insert Moulding: This process involves injecting a material over a preformed part to combine the two into a single component. This is often used to add a soft touch to a hard part, such as a handle.

2. Thin-wall Moulding: This technique is used to produce thin plastic parts. The process requires a special mould and machine design to ensure the plastic flows properly.

3. Micro Moulding: This is used to manufacture very small parts for applications in industries such as medical and electronics.

Applications of Injection Moulding

Injection moulding is used across a wide range of industries to produce a variety of products, including:

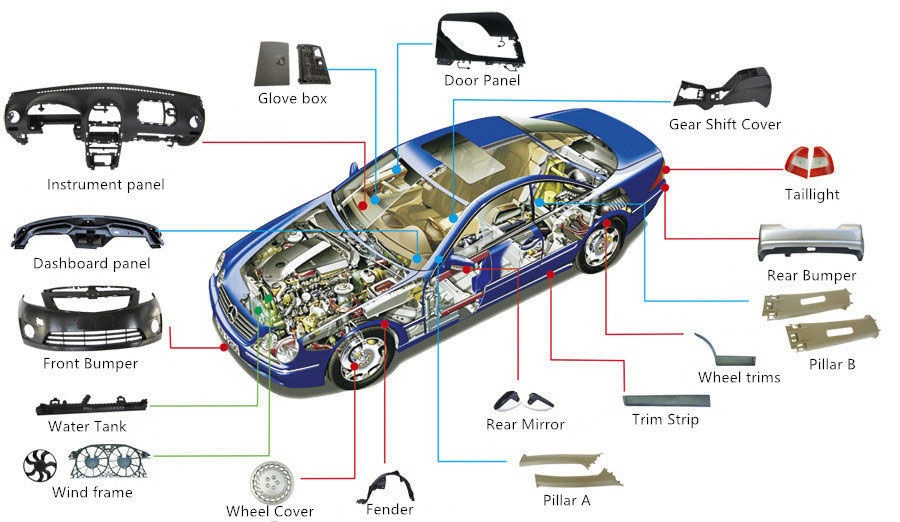

- Automotive parts

- Toys

- Household appliances

- Medical devices

- Plastic containers and packaging

Conclusion

Injection moulding is a versatile and efficient manufacturing process that plays a crucial role in many industries. Understanding this process can provide valuable insights into the production of many everyday items and open up new possibilities for innovation and design. Whether you're considering a career in manufacturing or just curious about how things are made, injection moulding is a fascinating topic to explore.

Stay tuned for more posts where we'll delve deeper into the world of manufacturing and explore other interesting topics. Happy learning!

コメント